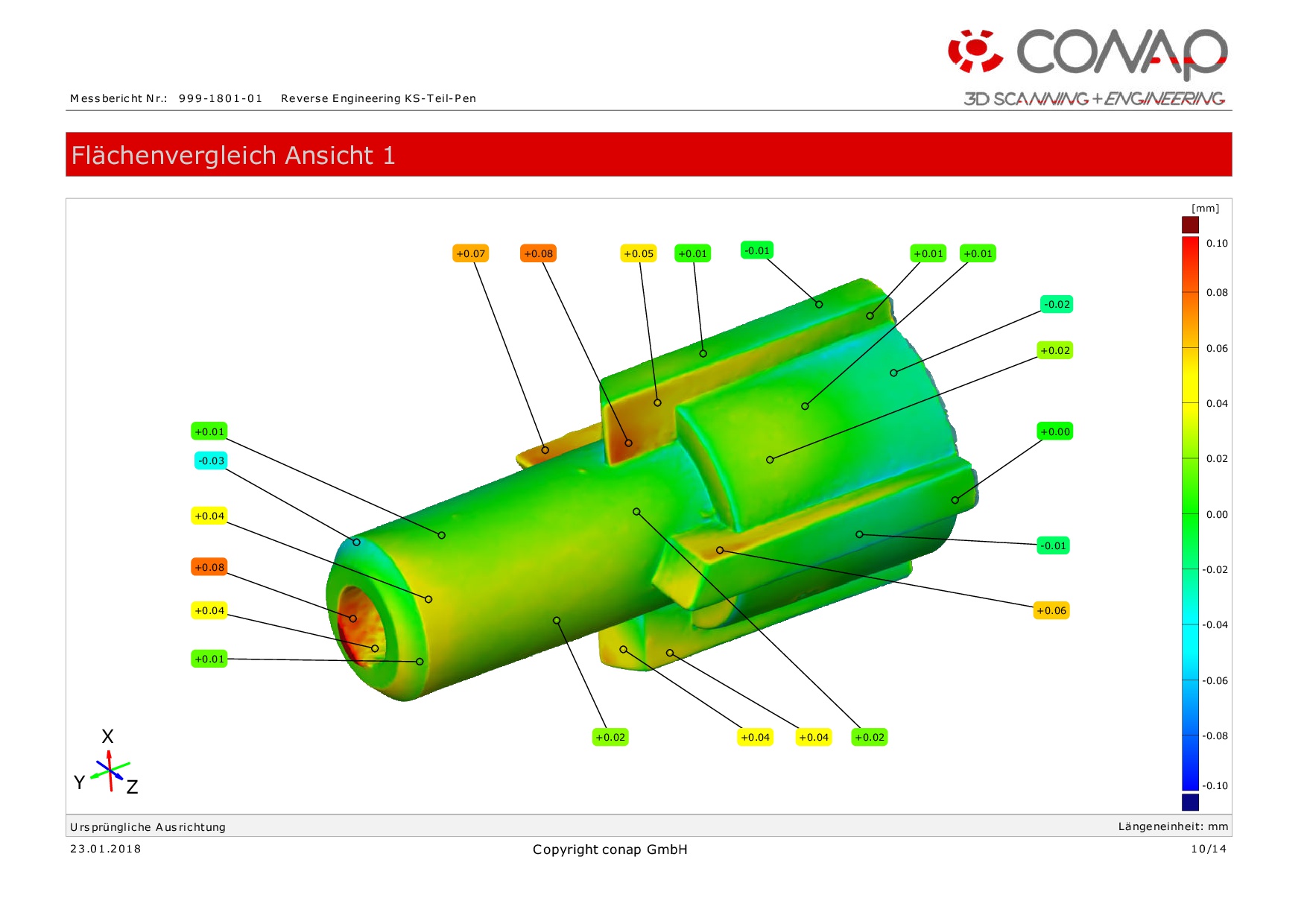

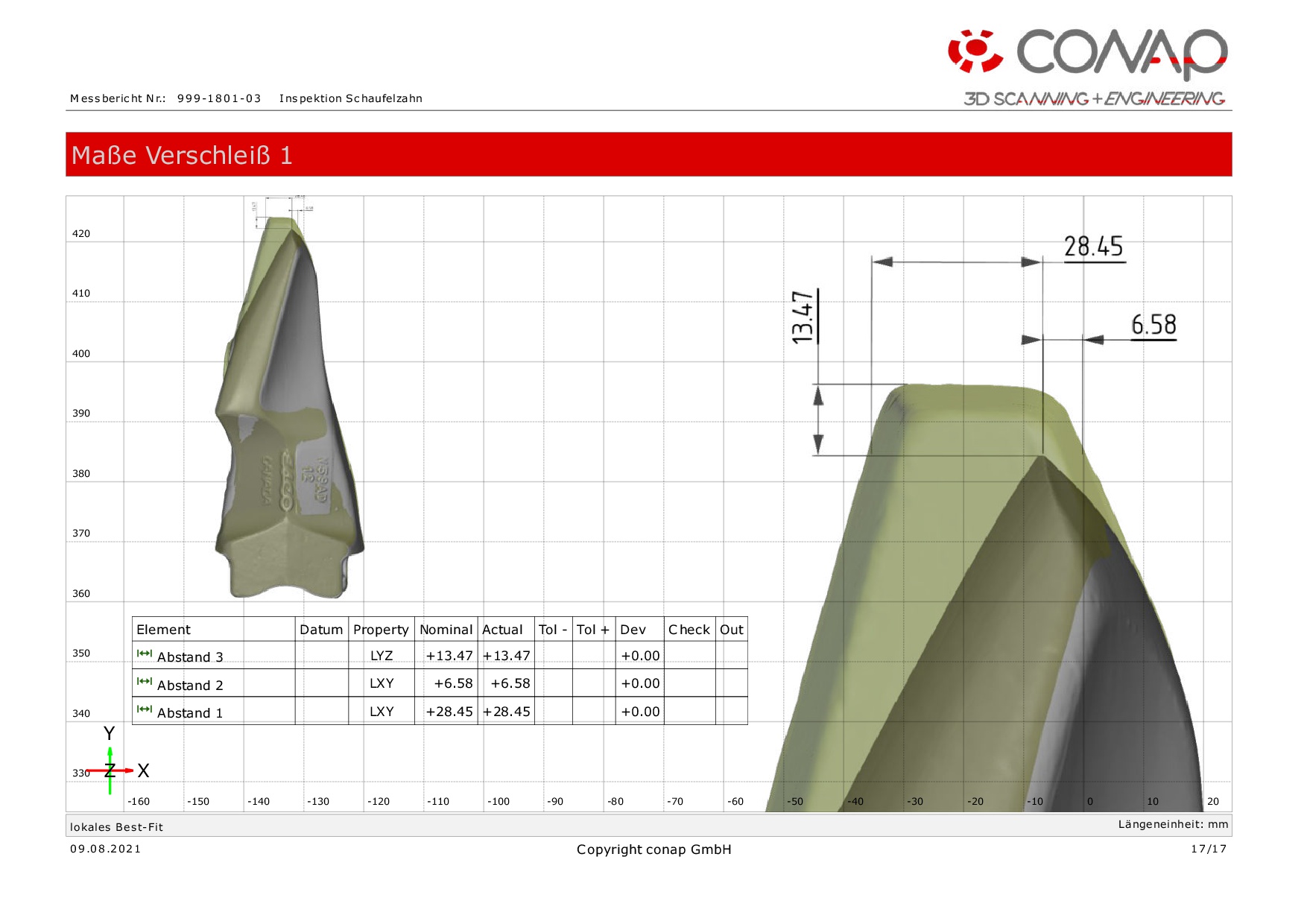

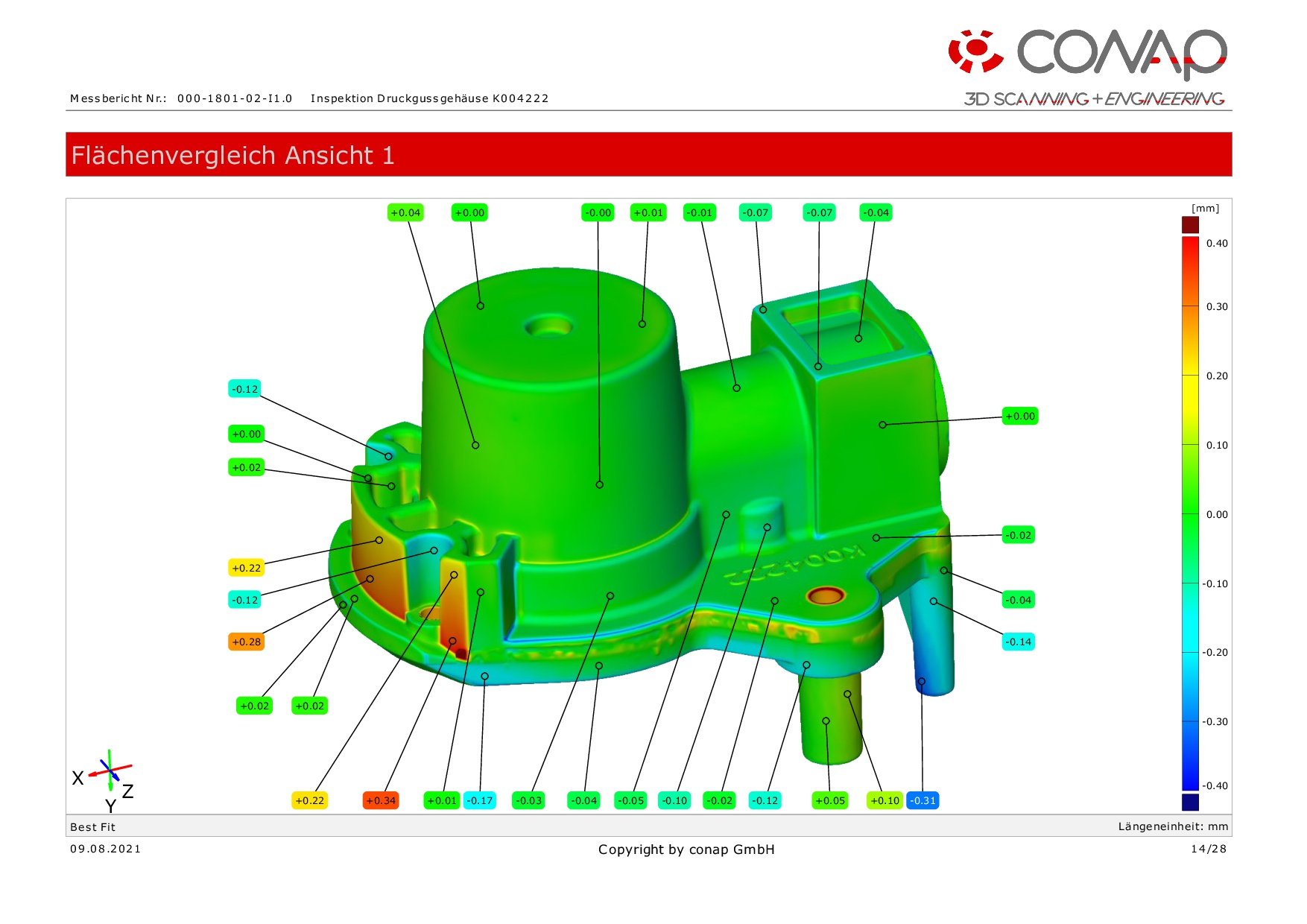

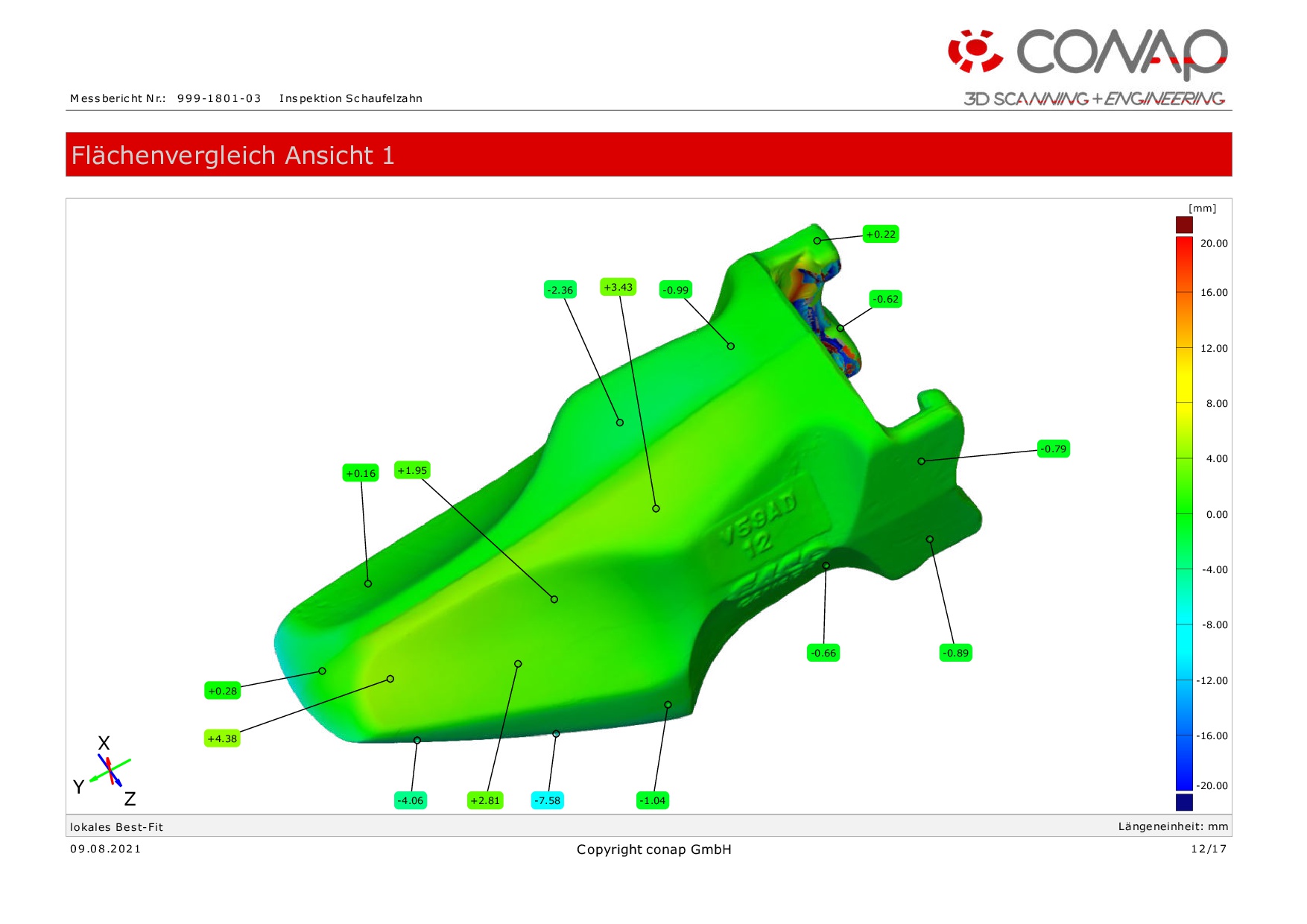

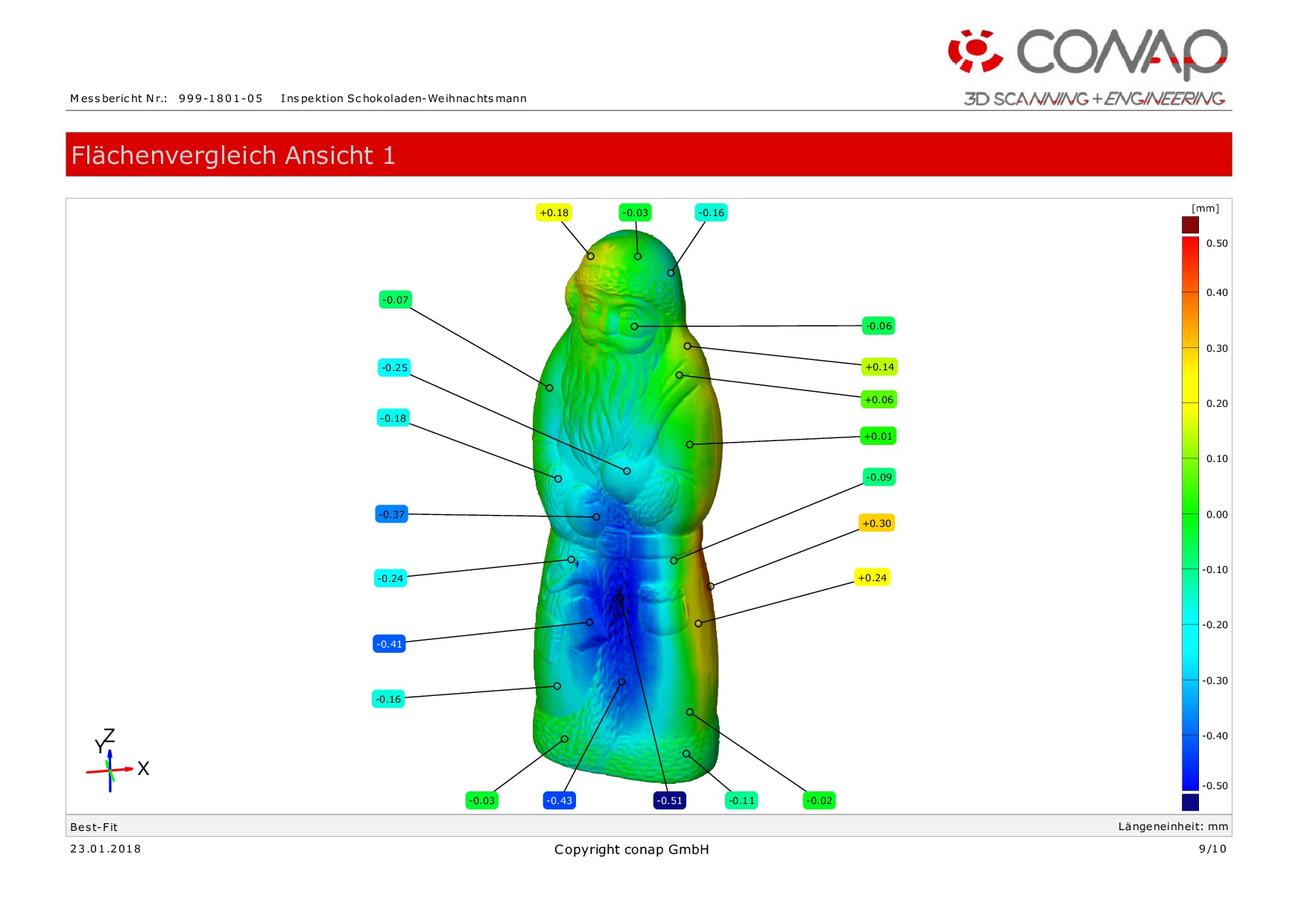

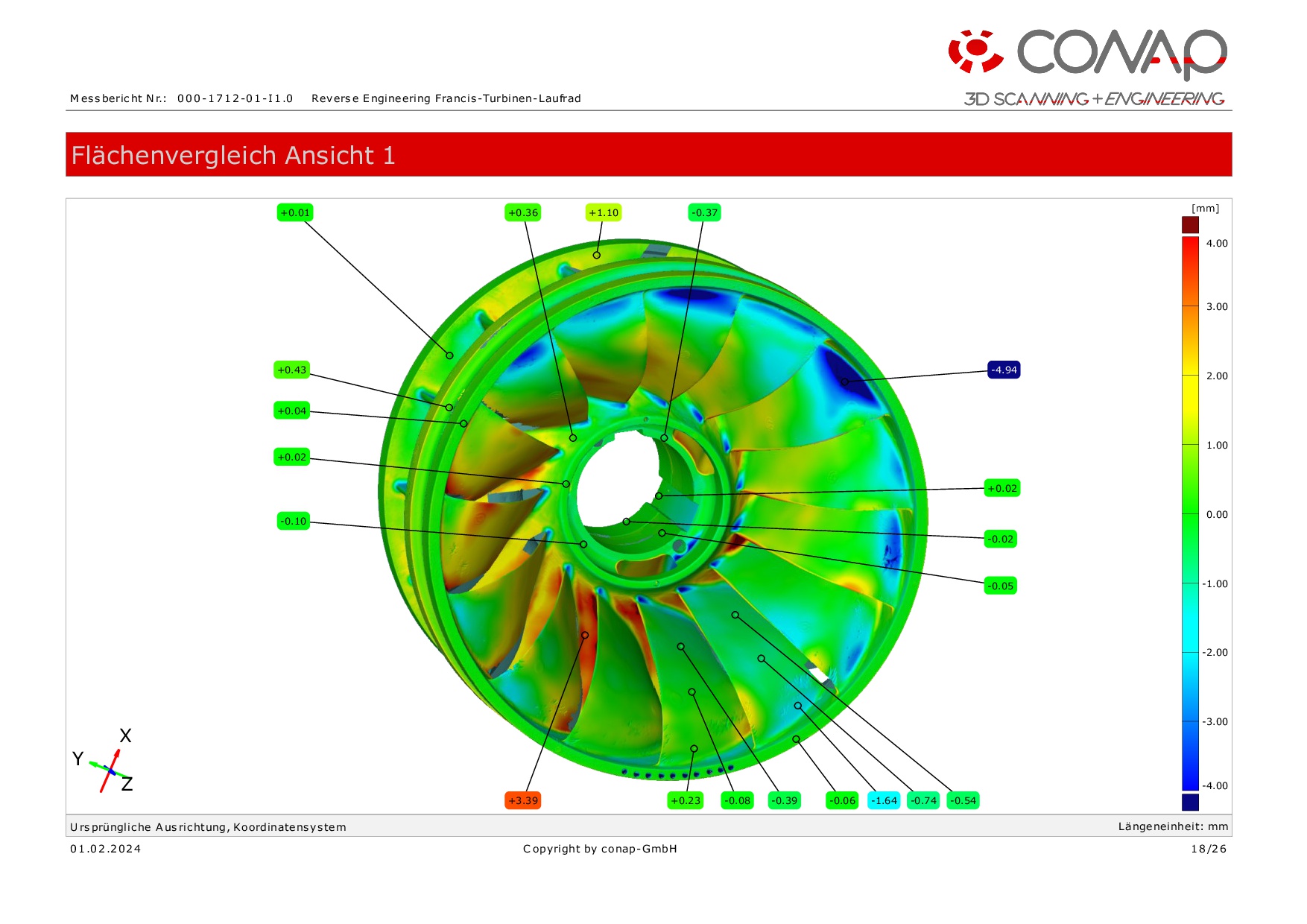

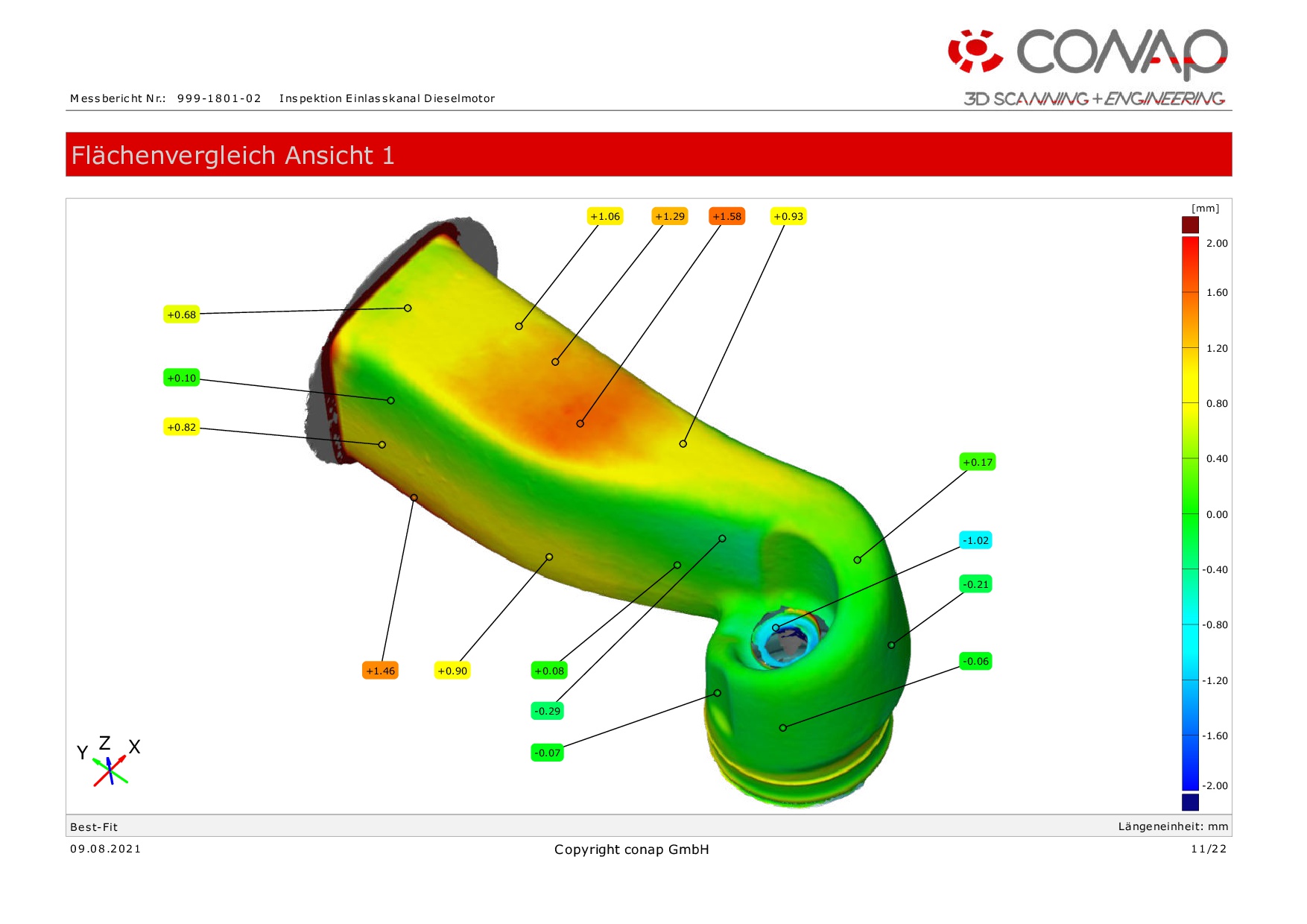

The data generated during 3D scanning (actual data) reflects your component as it was manufactured. Due to its level of detail, this data is ideally suited to be compared with the CAD data (target data) according to which your component was manufactured. To do this, we virtually align the scan data and the CAD model using 3D inspection software (ZEISS-Inspect Pro Optical 3D, formerly GOM-Inspect Professional) and create measurement reports in which we compare the target and actual models. The result is a 3D geometry check of the entire component.

3D Scanning

3D quality control, geometry control

3D quality control

target-actual comparison, 3D geometry control, area comparison

Apart from the complete geometry comparison of component against CAD, we offer the possibility to:

- Detection of manufacturing errors

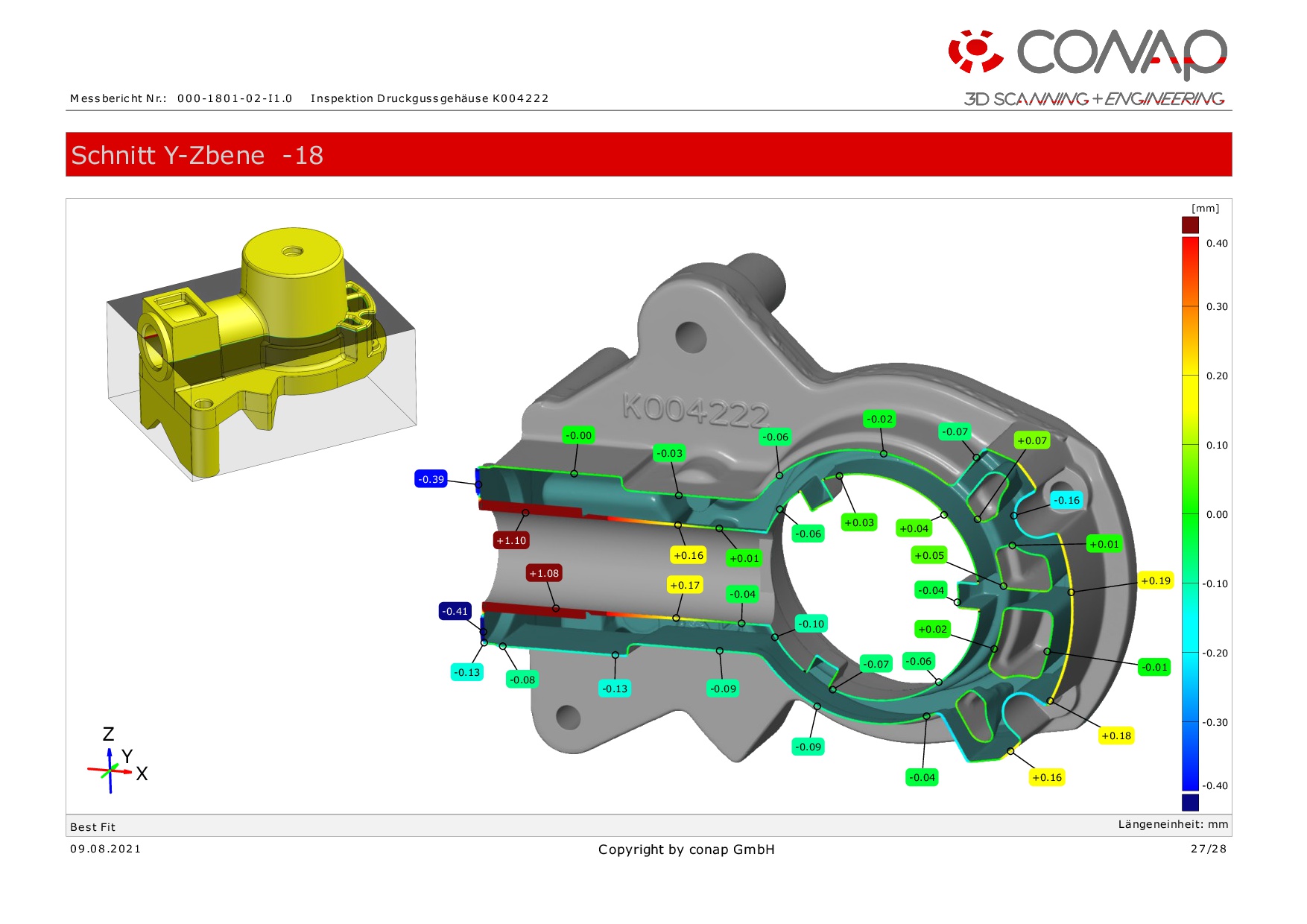

- Creation and analysis of cuts on the component

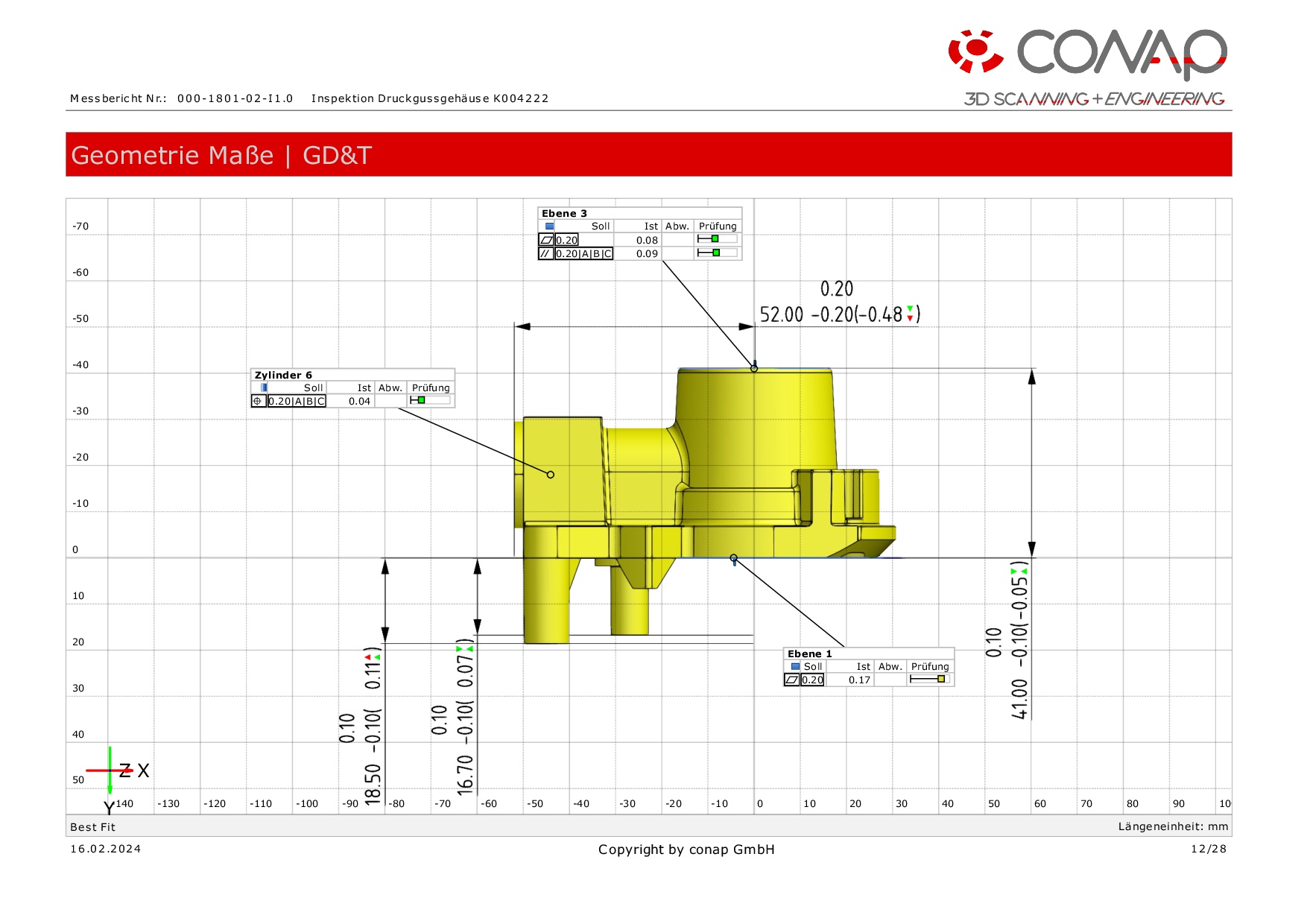

- Control of shape and position tolerances

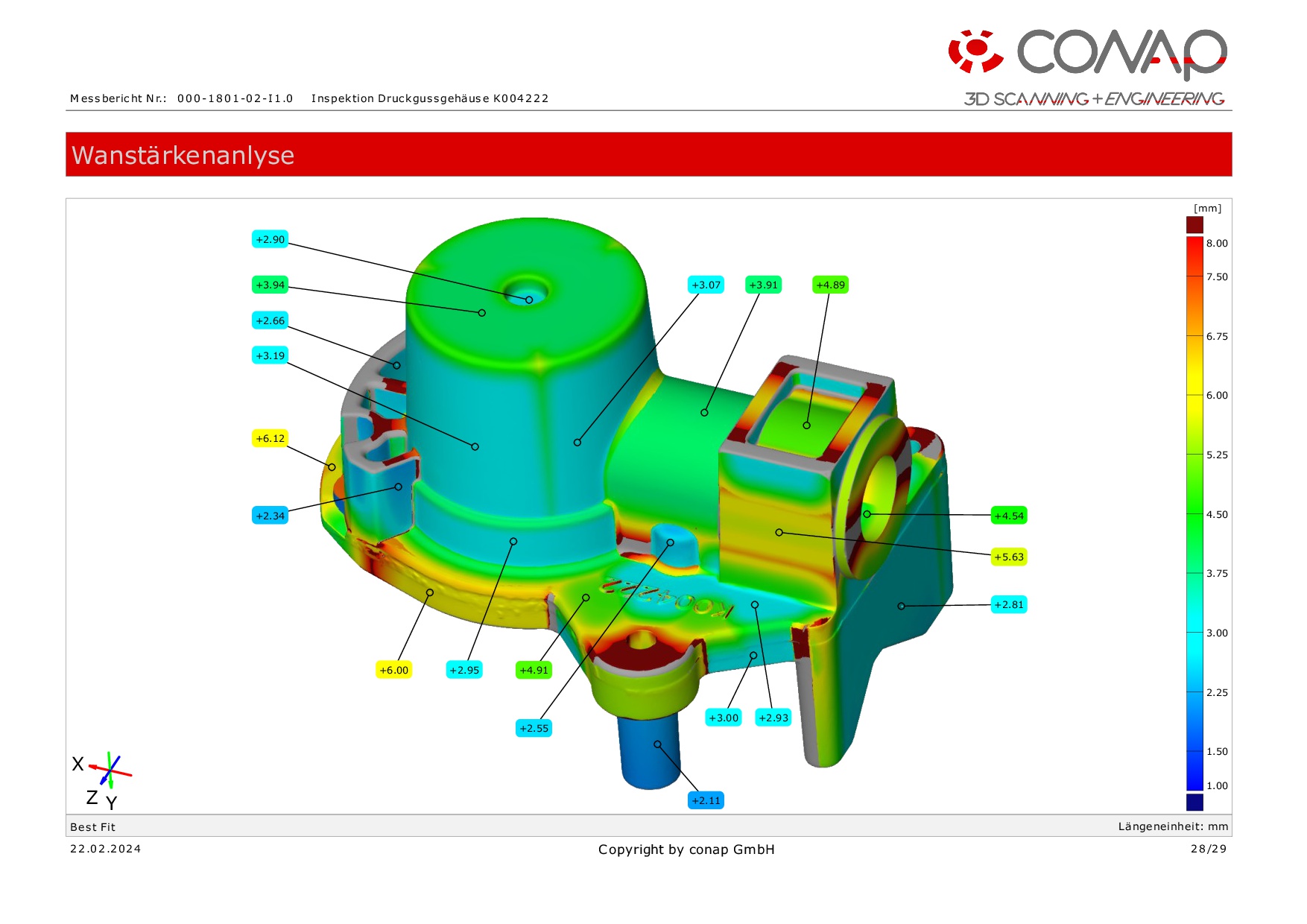

- Wall thickness control

- Fold analysis of sheet metal parts

- Competition analysis

- Comparison with previous measurements (wear, abrasion, deformation, corrosion …)

- Creation of initial sample inspection reports (EMPB) or First Article Inspection (FAI)

This enables error detection very early in the manufacturing process. You get a precise overview of the quality of your component and can therefore save costs and time.

Information on comparison types:

Area comparison, target-actual comparison, false color analysis, false color analysis, control of form and position tolerances (GD&T), initial sample inspection report EMPB, FAI First Article Inspection, cross-section analysis, wall thickness analysis, comparison with previous measurements

Project reports created with Zeiss-Inspect, (GOM-Inspect)

Target-actual comparison, surface comparison, 3D quality control and quality assurance in mechanical engineering.

3D measurement data

3D measurement data is information obtained from measuring a physical object or assembly in three dimensions. This data can capture various parameters such as size, shape, distances, and positions.

In terms of inspection, 3D measurement data can be extremely useful for evaluating the quality of products or parts. Here are some key applications:

Zeiss Inspect Pro Optical 3D / GOM Inspect

Zeiss Inspect Pro Optical 3D (GOM Inspect) is an advanced software solution from Zeiss, a company specializing in 3D inspection, metrology and quality assurance. This Pro license is used for 3D measurement data analysis and quality assurance. Here are some of the main features and application areas of Zeiss Inspect Pro Optical 3D. The special evaluation software for 3D measurement data is used in quality assurance, product development and production to check the measurement data from structured light scanners, laser scanners, coordinate measuring machines (CMM) and other measuring machines.

Features

1. 3D measurement data analysis

The inspection software enables the analysis of 3D measurement data from various sources, including 3D scanners and coordinate measuring machines (CMM).

2. Measurement data visualization

You can visualize 3D measurement data to better understand complex assemblies and geometries.

3. Advanced testing and analysis tools

Zeiss Inspect Optical 3D (GOM Inspect) offers a wide range of tools for inspecting, analyzing and verifying measurement data. This includes tolerance analysis, GD&T, deviation analysis and more.

4. Surface analysis

The inspection software enables the precise examination of surfaces and the evaluation of surface quality and texture.

5. Reporting

You can create reports that summarize measurement results and inspection data and use them for documentation and communication.

Applcations

1. Manufacturing industry

Zeiss Inspect is widely used in manufacturing and production to monitor and ensure the quality of manufactured parts and assemblies.

2. Quality control

The software is used for quality control processes to ensure that products meet specified tolerances and standards.

3. Research and development:

The software is used for quality control processes to ensure that products meet specified tolerances and standards.

4. Summary

Zeiss Inspect Optical 3D (GOM Inspect) is a powerful solution for companies and professionals who need to analyze high-precision 3D measurement data and perform quality assurance tasks.