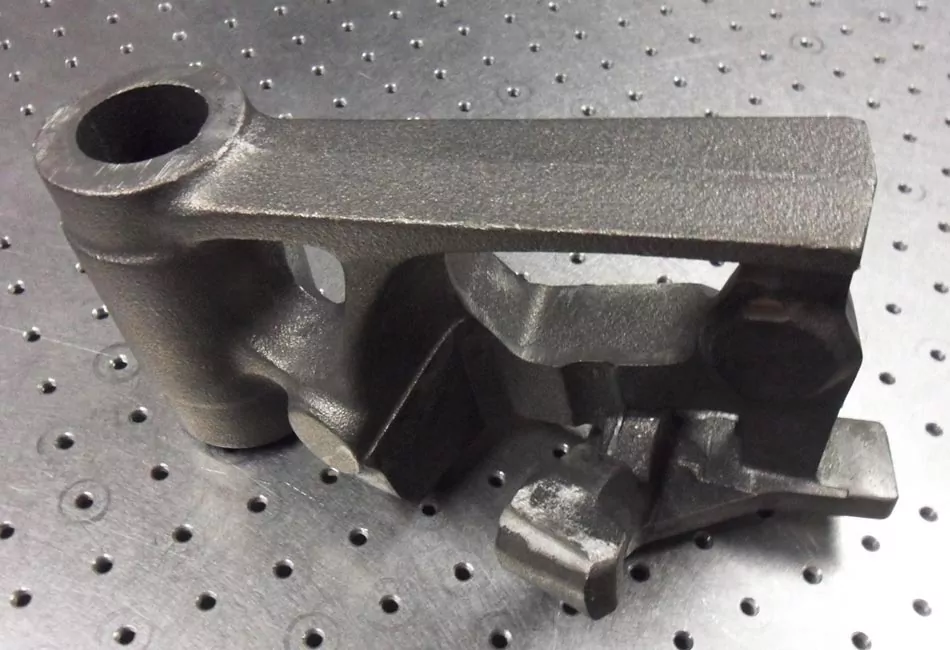

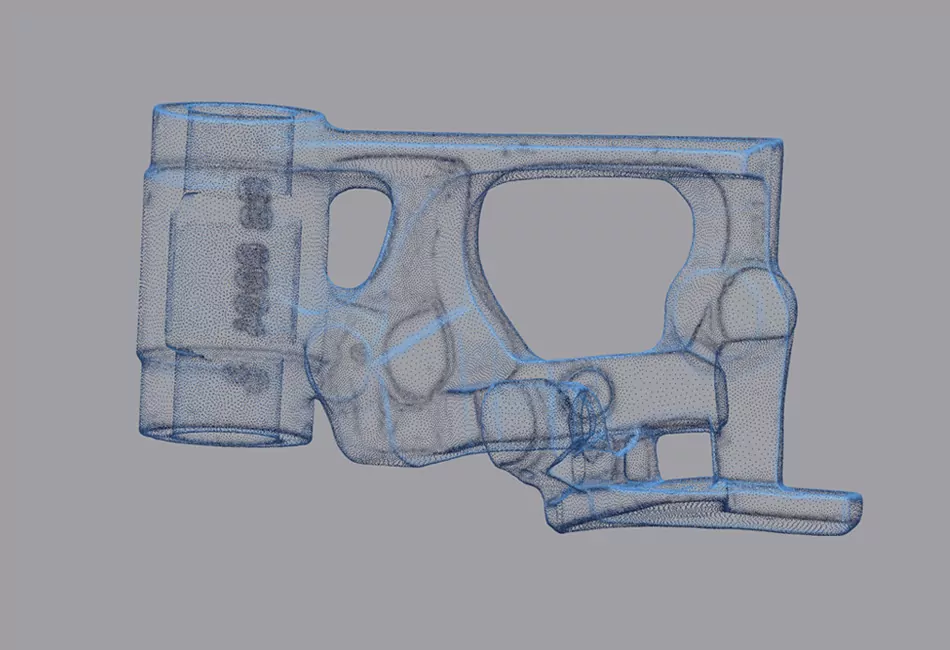

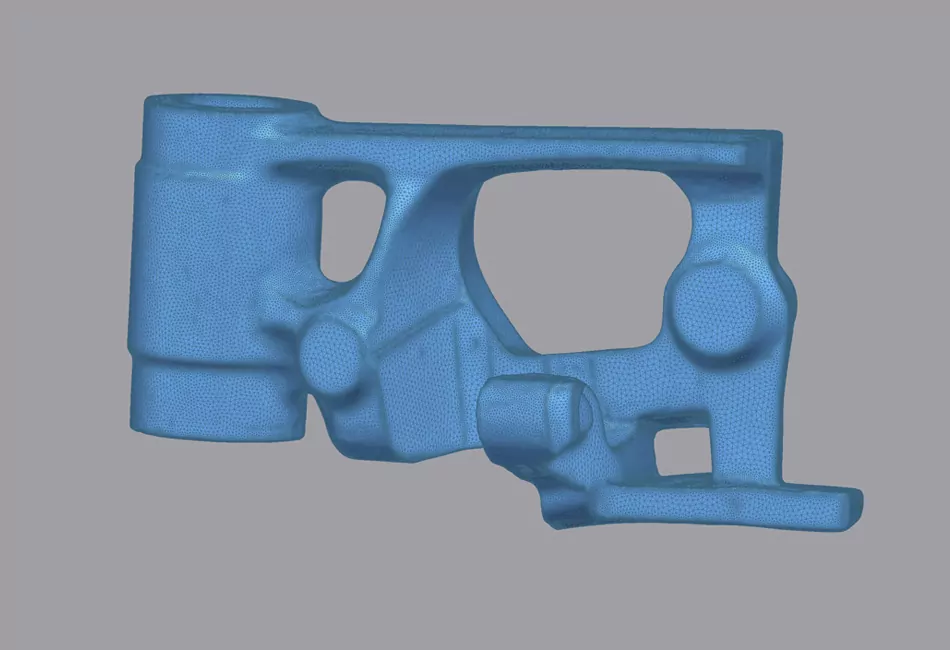

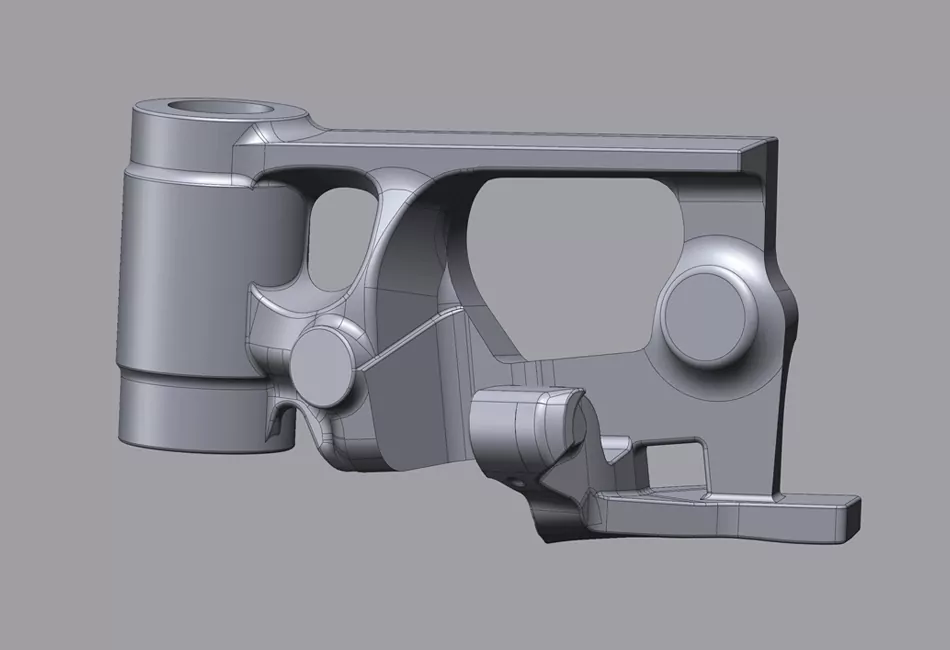

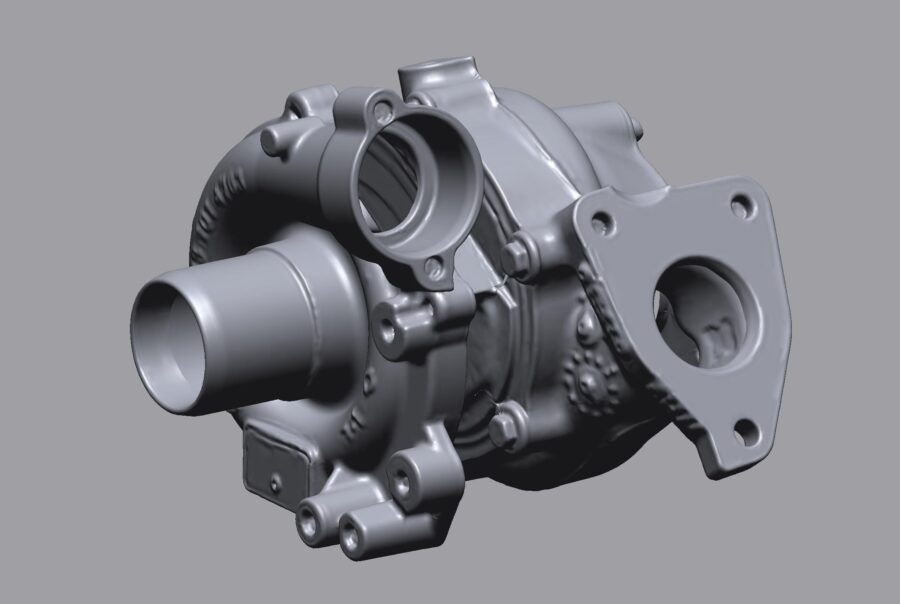

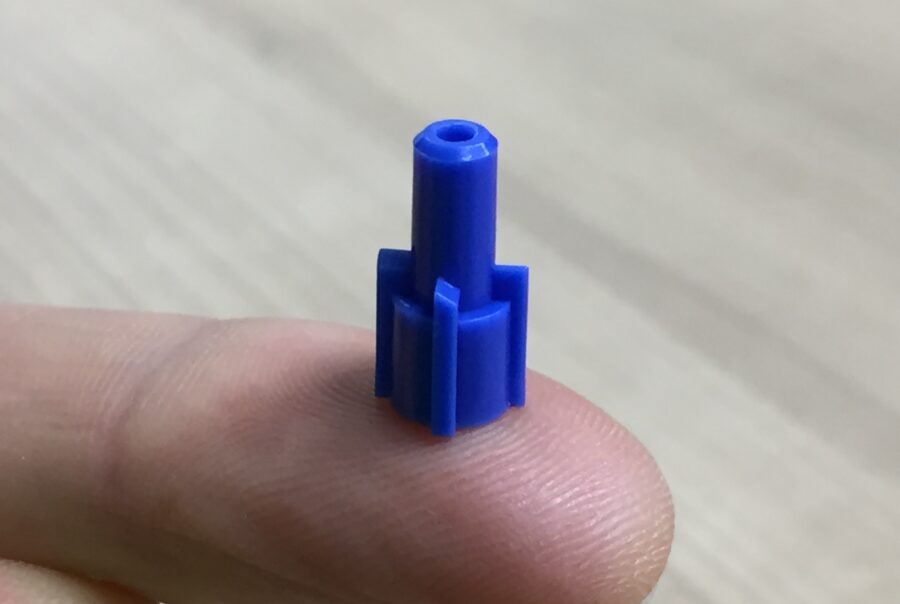

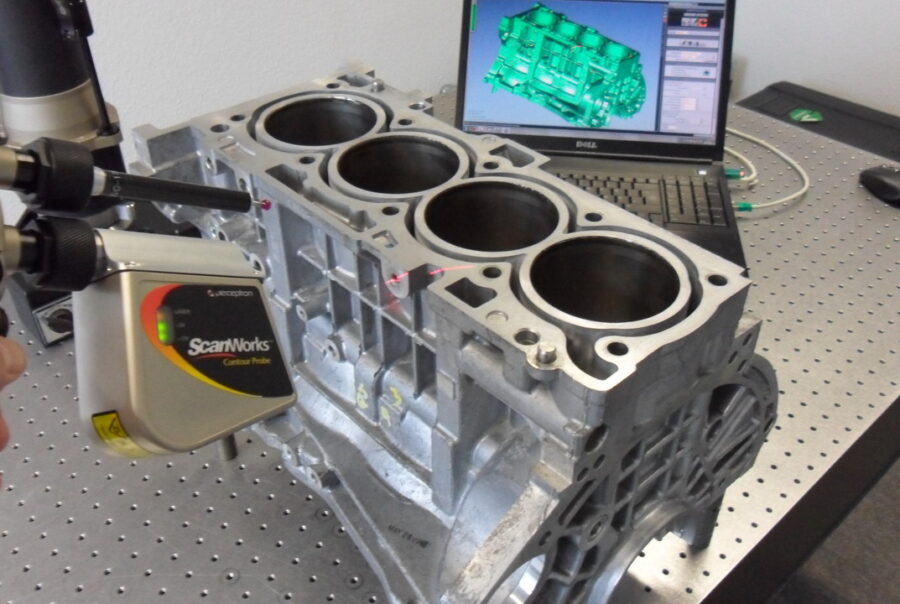

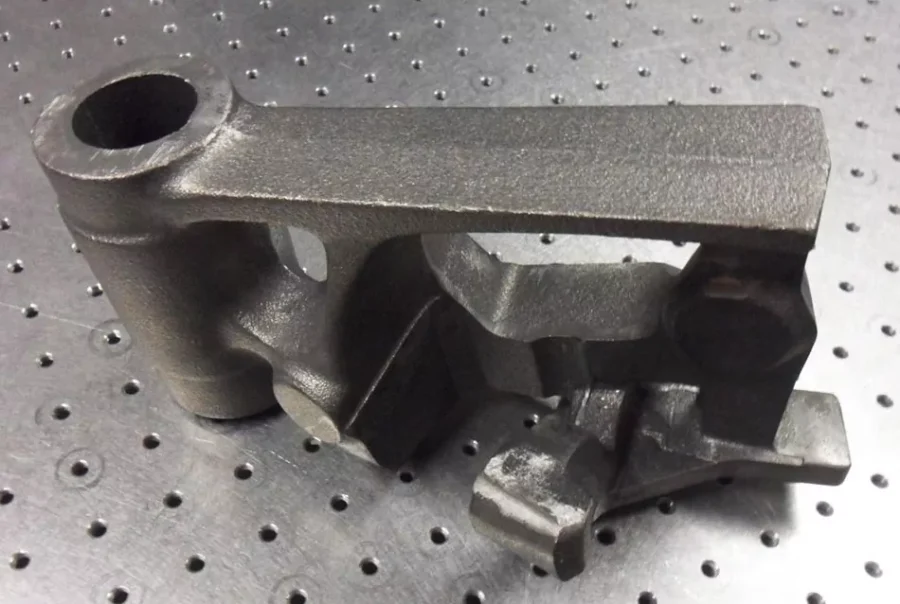

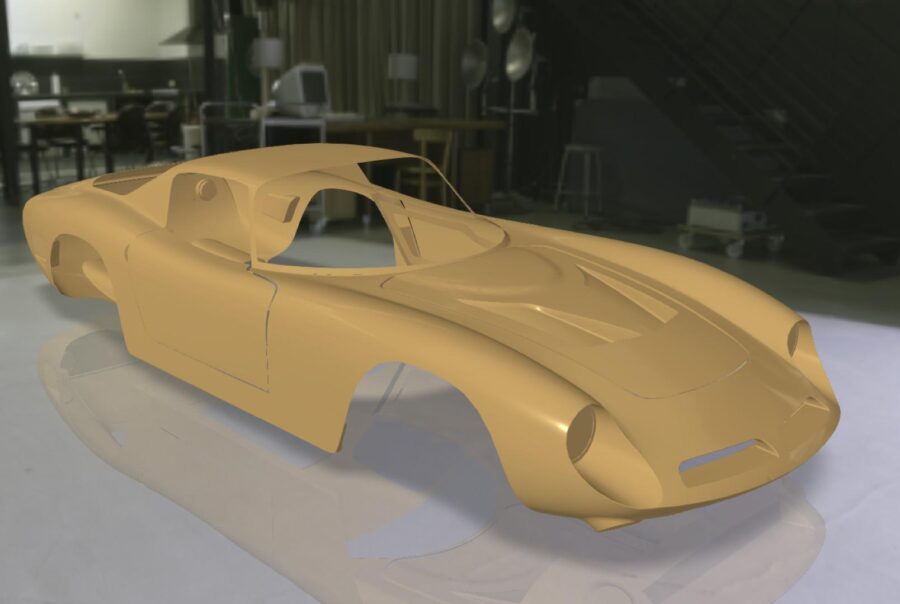

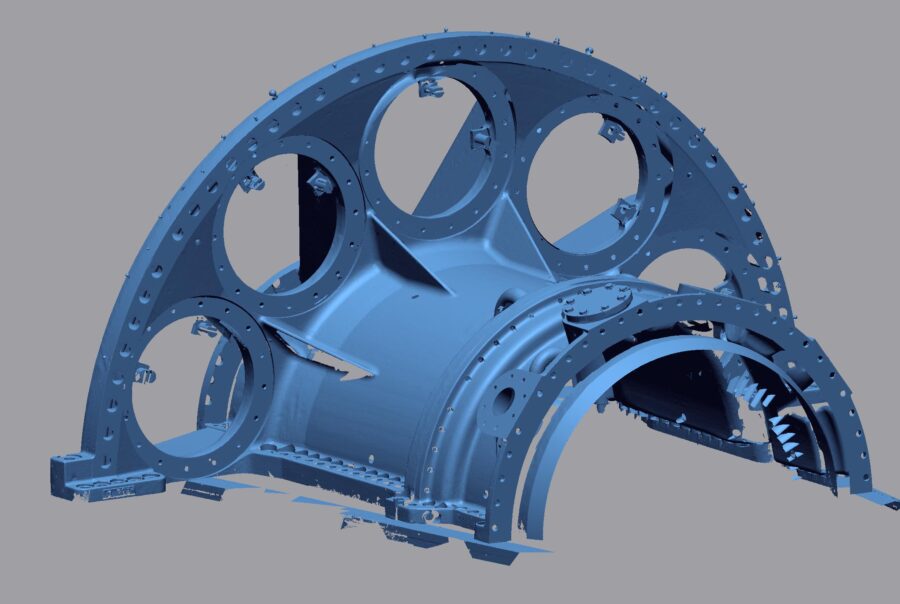

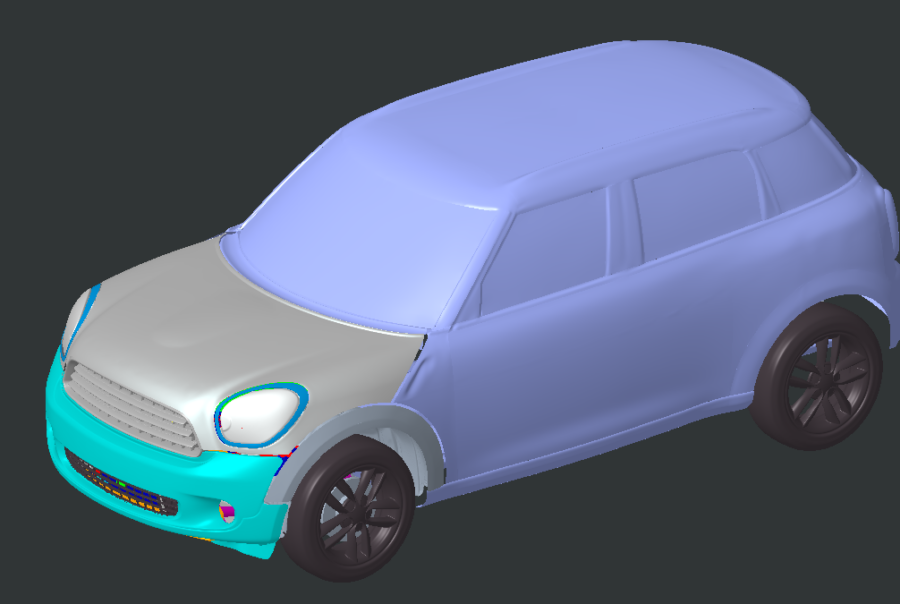

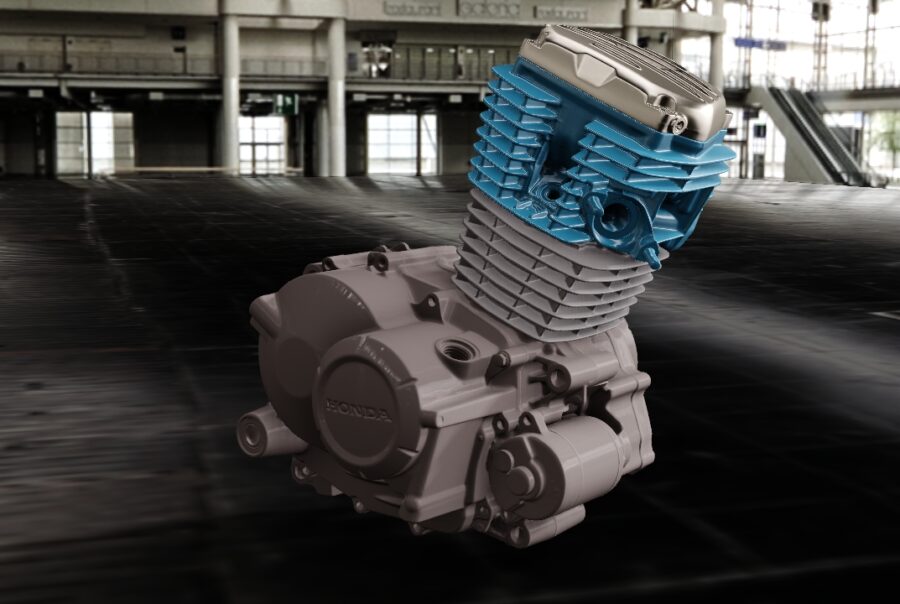

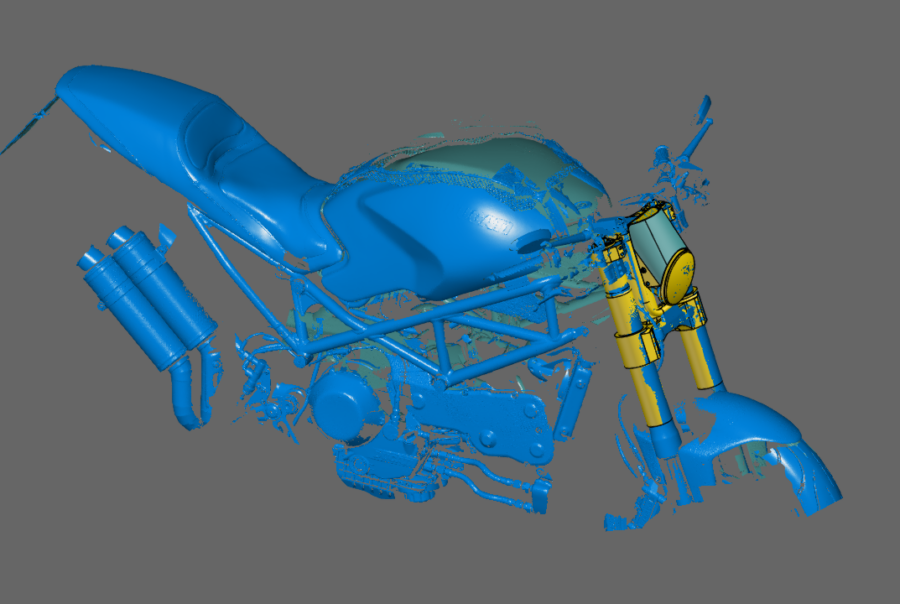

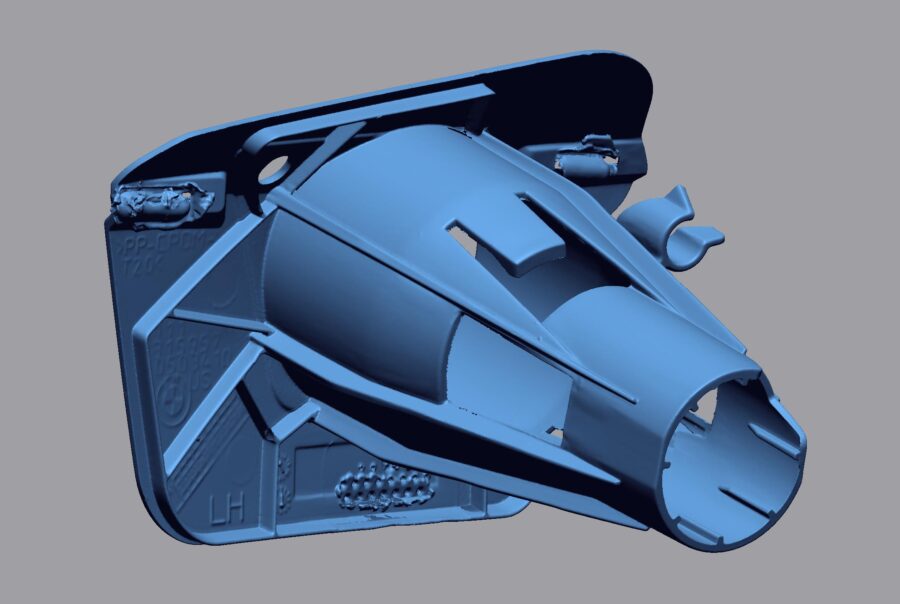

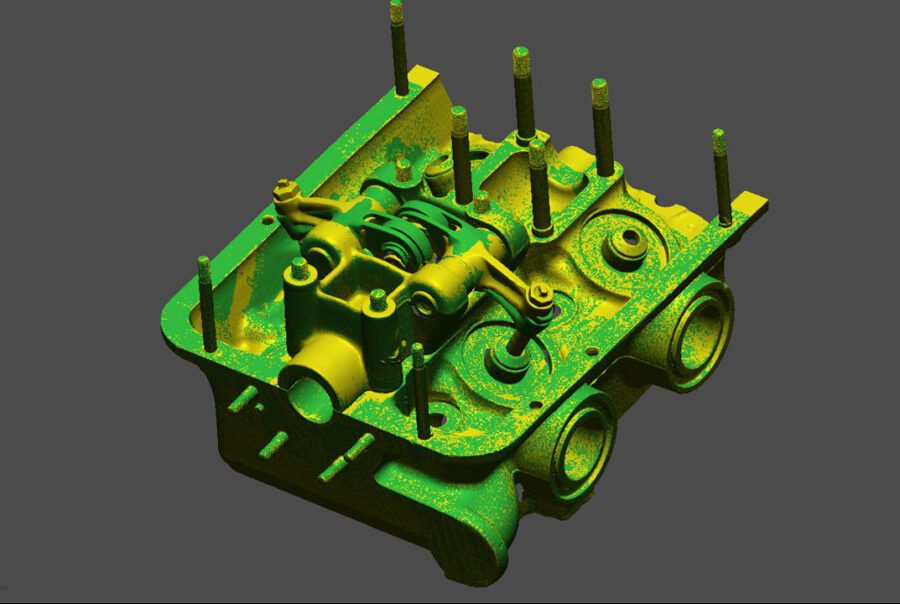

Surface reconstruction is part of the reverse engineering process, in which existing objects or components are understood and digitally reconstructed through analysis and reproduction. In recent years, 3D scanning has become an indispensable tool for this demanding task.

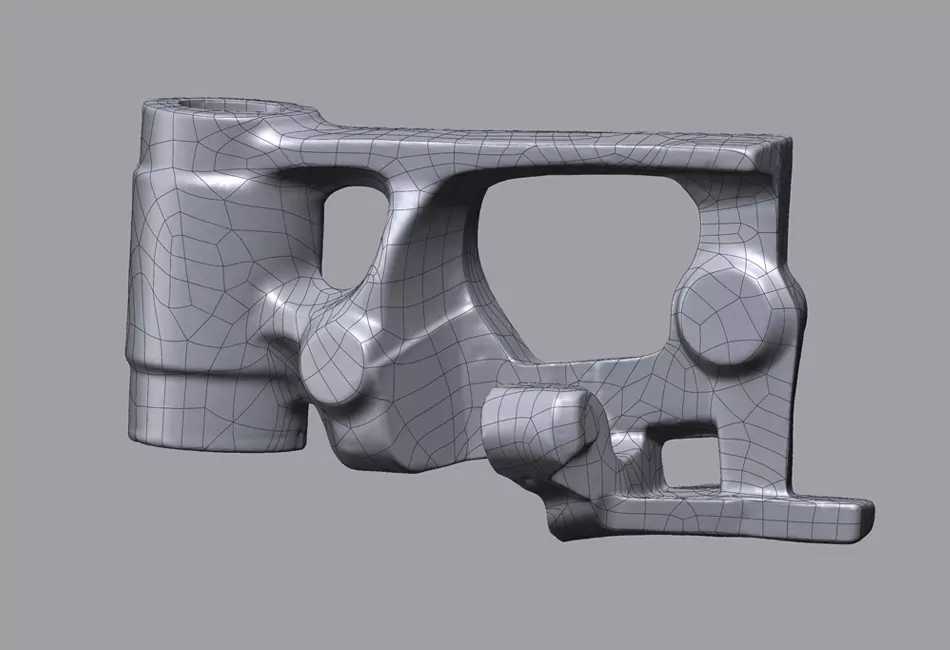

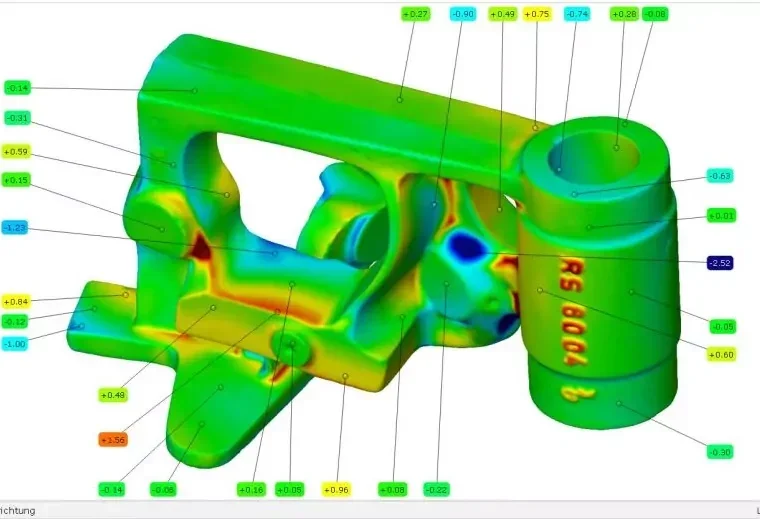

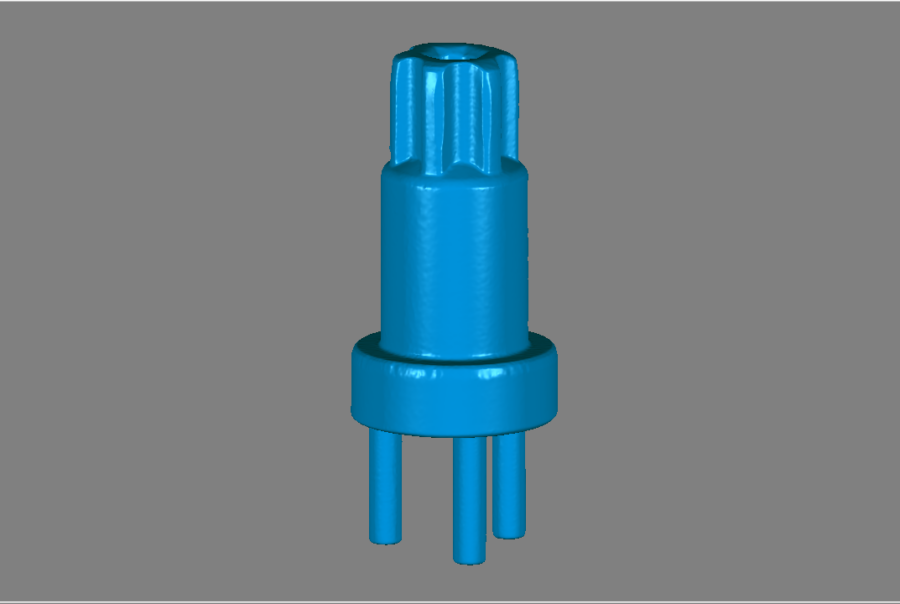

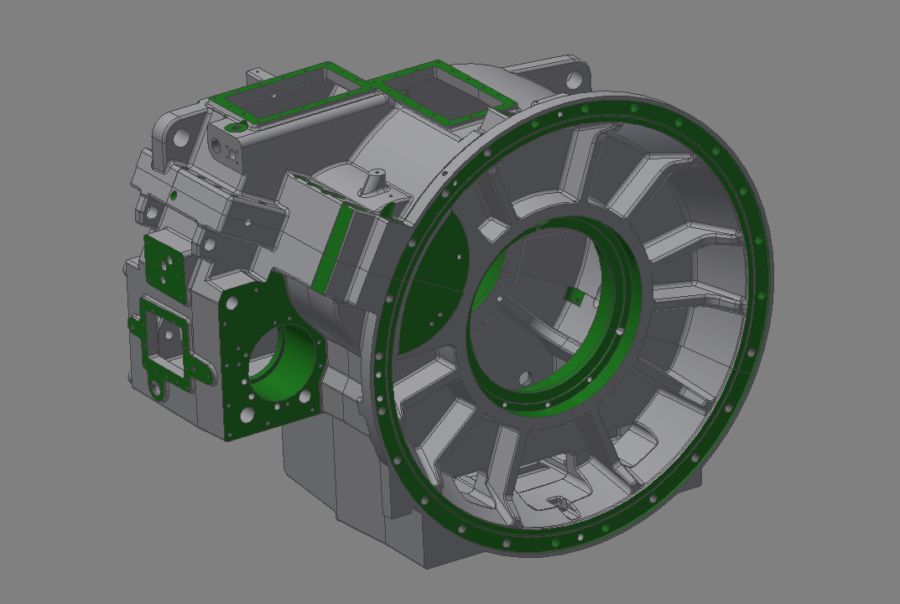

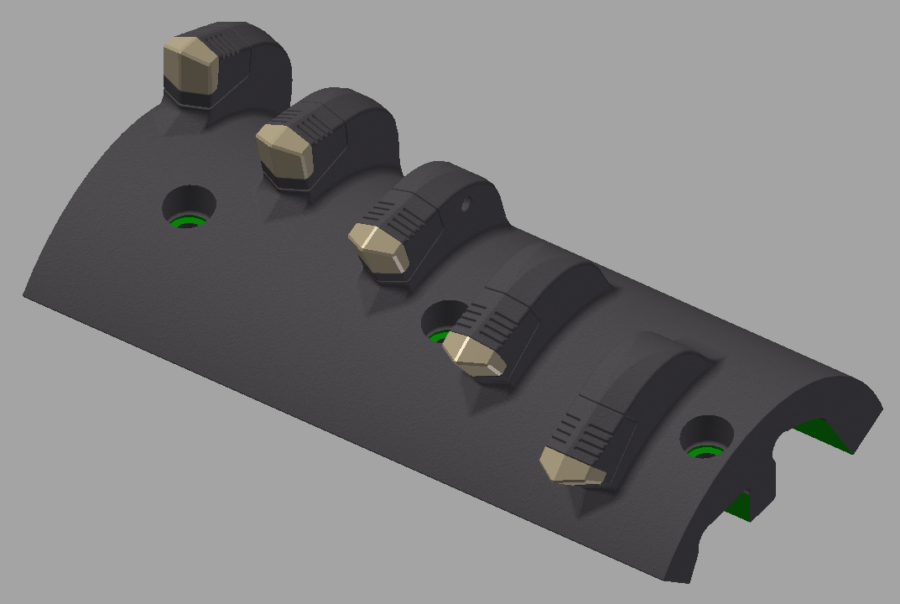

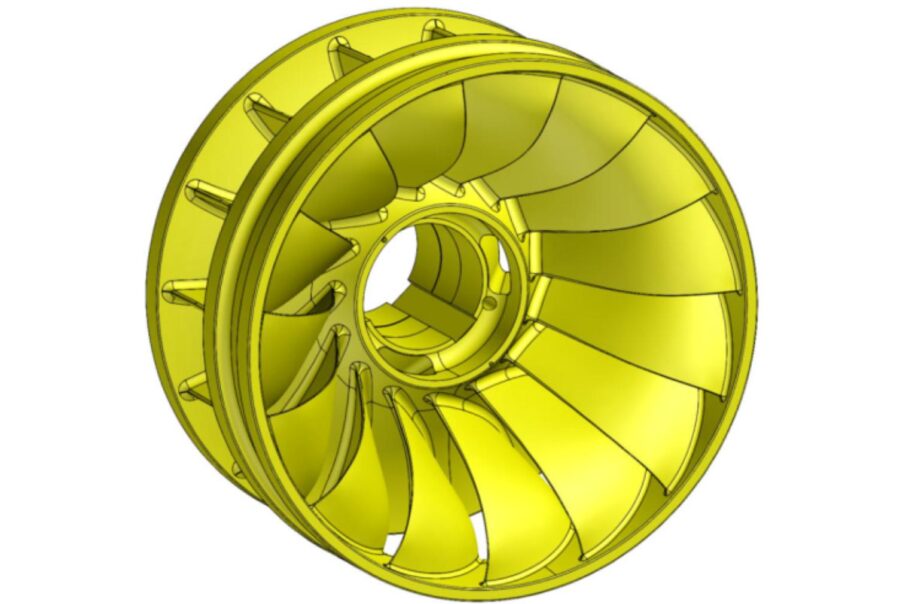

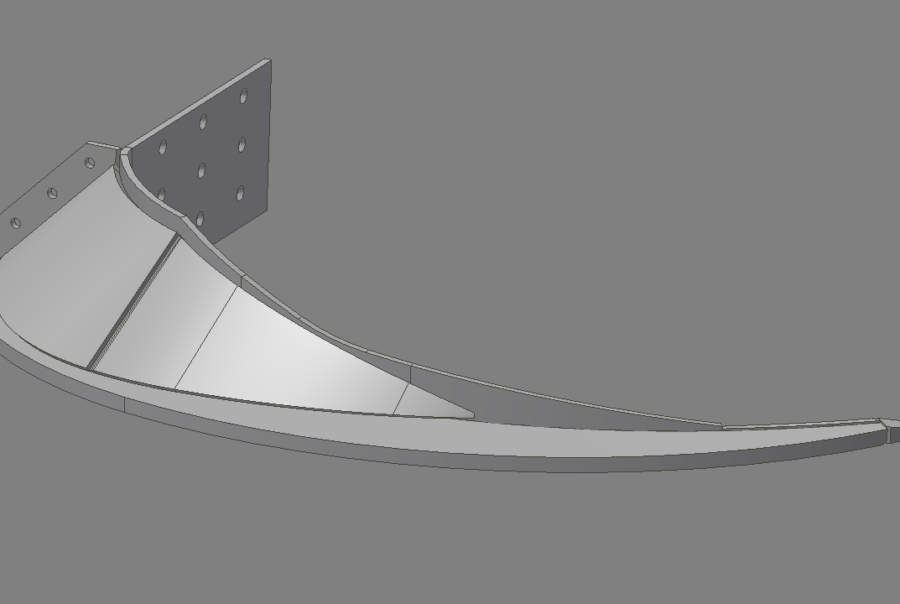

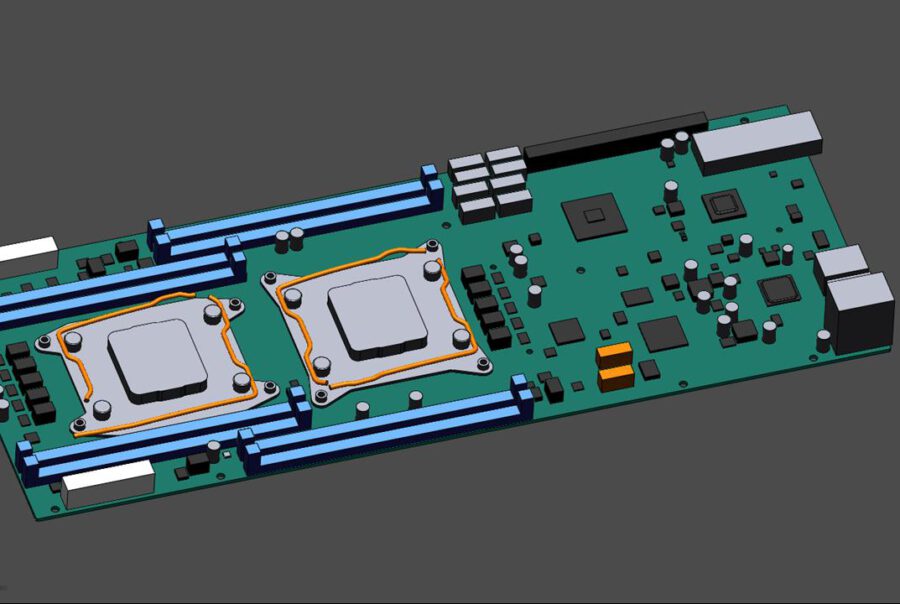

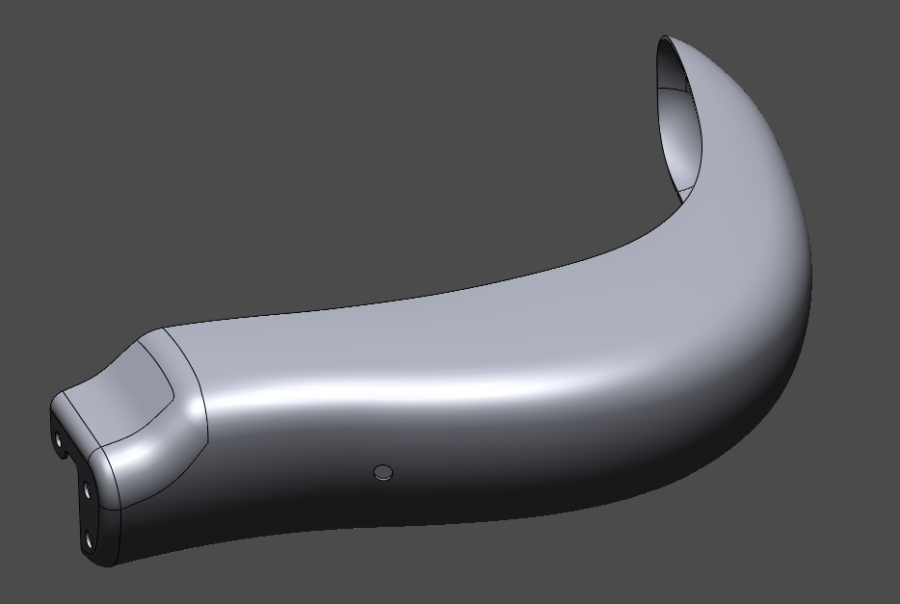

For 3D close-range scanning, we use mobile 3D scanners, the T-Scan LV laser scanner from Zeiss (Steinbichler) or the Comet L3D stripe projection scanner from Zeiss (Steinbichler). With these 3D scanners, we can digitize components of almost all sizes. The accuracy of the scanners is between approx. 6 µm and approx. 200 µm, depending on the measurement volume. The scanners work without contact and can usually scan almost all surfaces without object markers. We prepare the scanned point cloud of the object to be digitized using the Geomagic Design X (Rapidform XOR) software to create a CAD model. CAD models are created either through exact surface reconstruction or through parametric reconstruction of the model using a 3D CAD system. Both fall under the term reverse engineering. The 3D CAD systems we use are Creo (Pro/Engineer) and Autodesk Inventor.